| ITU-T G.652.D | Characteristics of a single-mode optical fiber |

| IEC 60794- 1- 1 | Optical fibre cables-part 2: Generic specification-General |

| IEC 60794- 1-21 | Optical fiber cables- part1-21-Generic specification-Basic optical cable test procedure-Mechanical test methods |

| IEC 60794- 1-22 | Optical fiber cables- part1-22-Generic specification-Basic optical cable test procedure-Environmental test methods |

| IEC 60794-3- 10 | Optical fibre cables-part 3- 10: Optical fiber cables-part 3- 10: Outdoor cables-Family specification for duct and direct buried optical communication cables |

Optical fibre cables supplied in compliance with this specifications is capable to withstand the typical service condition for a period of twenty-five (25) years without detriment to the operation characteristics of the cable.

| Item | Value |

| Operation temperature | -40 ºC~+70 ºC |

| Installation temperature | -20 ºC~+60 ºC |

| Storage temperature | -40ºC~+70 ºC |

| Static bending radius | 10 OD |

| Dynamic bending radius | 20 OD |

1.The unique second coating and stranding technology provide the fiber with enough space and bending endurance, which ensure good optical property of the fiber in the cable

2.Accurate process control ensures good mechanical and temperature performance

3.High quality raw material guarantees the long service life of cable

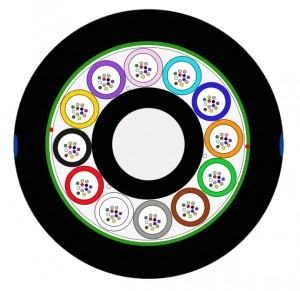

The color code of fibres and loose tube will be identification in accordance with the following color sequence, other sequence also is available. The color of the fillers will be black.

The color code of fibres and loose tube will be identification in accordance with the following color sequence, other sequence also is available. The color of the fillers will be black. | Fibre Color code TIA-EIA 598-B | ||||||

| 4~12F/T | 1 | 2 | 3 | 4 | 5 | 6 |

| Blue | Orange | Green | Brown | Grey | White | |

| 7 | 8 | 9 | 10 | 11 | 12 | |

| Red | Black | Yellow | Purple | Pink | Aqua | |

| Tube Color code TIA-EIA 598-B | ||||||

| 12F | 1 | 2 | 3 | 4 | 5 | 6 |

| Blue | Orange | PP filler | PP filler | PP filler | PP filler | |

| 24/48F | 1 | 2 | 3 | 4 | 5 | 6 |

| Blue | Orange | Green | Brown | PP filler | PP filler | |

| 36F | 1 | 2 | 3 | 4 | 5 | 6 |

| Blue | Orange | Green | Brown | Grey | White | |

| 96F | 1 | 2 | 3 | 4 | 5 | 6 |

| Blue | Orange | Green | Brown | Grey | White | |

| 7 | 8 | |||||

| Red | Black | |||||

| 144F | 1 | 2 | 3 | 4 | 5 | 6 |

| Blue | Orange | Green | Brown | Grey | White | |

| 7 | 8 | 9 | 10 | 11 | 12 | |

| Red | Black | Yellow | Purple | Pink | Aqua | |

| Cable size | |||||||

| Fiber number | 12 | 24 | 36 | 48 | 72 | 96 | 144 |

| Central Element | FRP | ||||||

| Fiber Coloring | Bule, Orange, Green, Brown,Slate, White, Red, Black, Yellow, Violet, Rose, Aqua | ||||||

| Fiber per tube | 12 | ||||||

| Loose tube color coding | Bule, Orange, Green, Brown,Slate, White, Red, Black, Yellow, Violet, Rose, Aqua | ||||||

| Number of rip cord | 2 | ||||||

| Armour | Corrugated steel tape | ||||||

| Outer jacket material | HDPE | ||||||

| Tape | Water-swellable | ||||||

| OD (mm) | 10.0 | 10.0 | 10.0 | 11.4 | 11.4 | 12.8 | 15.7 |

| Weight(kg/km) | 94 | 94 | 94 | 121 | 121 | 150 | 217 |

| Fiber Standards | TIA/EIA-492CAAB,IEC60793-2-50 Type B1.3, ITU-T G.652.D ISO/IEC11801 Ed2.2 |

| Water blocking | IEC 60794-1-2 F5 |

| Fiber | Single-mode ITU G.652.D | |

| Max Attenuation | 1310nm/1383nm/1550nm | 0.36dB/km/0.36dB/km/0.22dB/km |